There are methods for repairing pipelines such as using metal mechanical clamps or composite overwraps. However, these have a range of limitations.

SC Innovation were approached to design and evaluate a fibre-reinforced polymer matrix composite repair solution, equivalent to a metal mechanical clamp. Experiments were performed to validate the design methodology. Results from physical testing were compared to those from computer modelling.

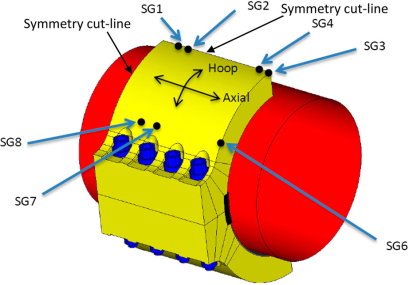

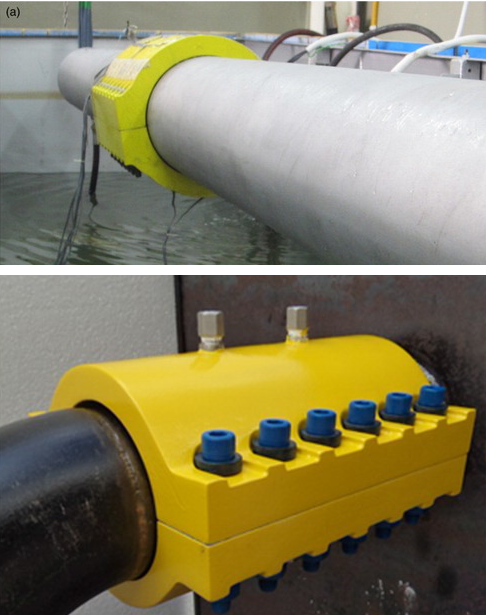

To test out the performance of the clamp in field conditions, a repair clamp for a 4-in nominal diameter propane piping was fabricated. Two main sets of pressure tests were undertaken; short and long term. For the long term test a purpose-built pressure test system was used to conduct the long-term survival test for 1000 hours. A Finite Element (FE) simulation model was created in LS-DYNA to simulate the tests outlined above. Testing demonstrated the clamp to adequately hold 10.5 MPa pressure for 1 minute at RT, 65 and 80°C, with no visible or audible signs of failure. The functionality of the clamp was not compromised after the long-term survival test.

The Composite Clamp

- More Effective

As well as providing uncompromising strength and reliability to the repaired structure, the composite clamp offers greater corrosion resistance compared to existing alternatives. It is also more effective at leak containment due to the use of rubber seals. The composite clamp weighs less than 7 kg in total. This is three times lighter than similarly sized standard metal clamps, adding no significant load to the pipeline.

- Lower Cost

A vacuum bag resin infusion was used to produce the composite clamp. Materials were selected based on a requirement for simple and inexpensive tooling, rapid turn-around on short-runs or one-off products and low-cost raw materials. Carbon fibre reinforcements were initially considered but dismissed in favour of glass fibres which have a lower cost. Also, unlike carbon fibre, glass fibres do not have the potential for causing galvanic corrosion of the steel pipe. The result is a product which is cost efficient.

- Simpler to install

Clamps can be pre-fabricated rather than requiring in-field fabrication. The surface finish requirements of clamps are far less stringent than those of overwrap repairs. As it is only 7kg the clamp can be easily handled by a single person, making it much easier to install.

Please click here to view the fully published article. Please contact us to discuss your engineering challenge